Where other technologies struggle, Computer Vision thrives

The tracking of equipment and supply chains is an essential part of running a business effectively. Insufficient or defective tracking causes confusion and results in a waste of time and resources – ultimately creating bottlenecks that slow down your whole business. To avoid this, you need your Equipment & Supply Chain Tracking to be on point, and for that, you need sensors to collect data. Using RFID- or NFC-tags is a popular approach, but in many cases, this method faces a number of issues.

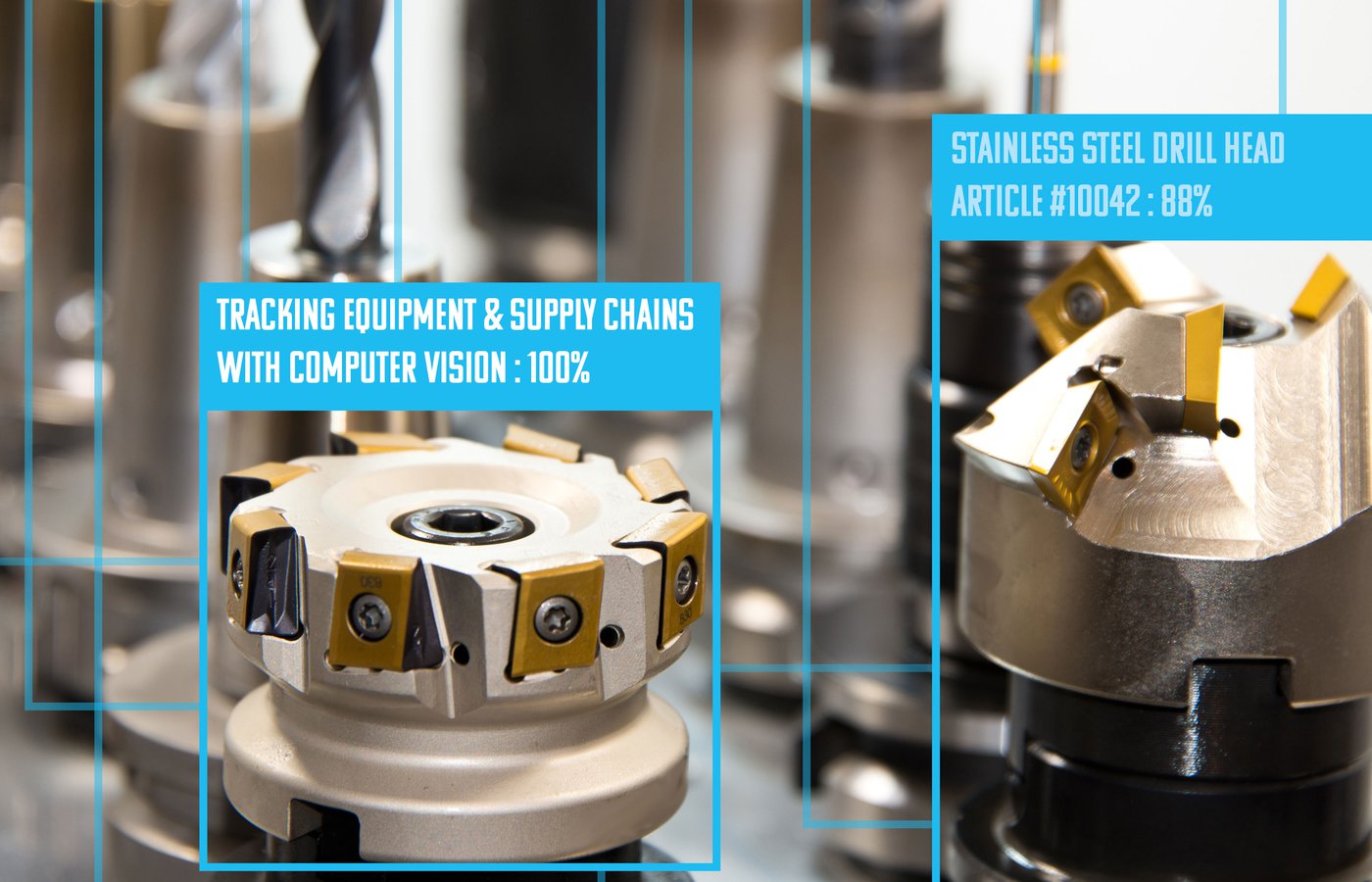

Retrofitting your equipment with tags or barcodes can be costly, or the technology might not fit your business case in the first place. For example, Radio-Frequency Identification (RFID) tags do not work well nearby metal, which reflects the energy they emit, which means it is harder to use RFID tags to track equipment made of metal. In such cases, computer vision can be a handy tool to help you track your equipment and supply chains effectively.

How does it work?

Thanks to recent advances in computer vision, you can now detect and track objects in real-time using a standard laptop. This is possible due to an open and collaborative data science community and accelerating progress in hardware. I’ve built a simple prototype this week using a Raspberry Pi, which is a tiny computer suitable for experimenting. This prototype can detect objects three times per second – impressive for the computer’s low power!

The above setup takes advantage of MobileNets, a type of model that has been designed to run on restricted resources while maximizing accuracy. Out of the box, this model can recognize 80 common objects such as people, cars, planes, and bicycles.

These models can also be retrained to track your equipment

A useful property of these models is that they can be easily retrained to detect new objects, a process known as transfer learning. This type of model tweaking works well because the model learns low-level concepts such as edges as well as high-level concepts like wheels. Transfer learning allows you to tweak these learned concepts and apply them to detect your equipment. This is handy because retraining existing models means that you will only need a few hundred labeled images to get results. So, instead of recognizing me and our marketing guy goofing around the office, we can easily train the model to recognize almost any type of items you need to track.

Coupled with better models, the hardware is also getting cheaper and improving. You can already run these models locally on existing hardware connected directly to a camera or video stream, which is known as edge computing. There are a number of initiatives to make even better edge devices, such as Google’s Edge TPU and Nvidia’s Jetson Nano. I’m personally excited because these new devices are making more cases viable.

You show us the problem, we bring the tools

At Bluugo, we see computer vision as another sensor that can keep track of your equipment and production lines. We can combine this technology with your existing data and sensors in our Tracking Cloud™ platform to give you a digital version of your business. This single view of your business will enable you to manage and optimize your equipment and supply chains with ease and streamline your processes.

Think you could benefit from applying Computer Vision within your business? Get in touch today and we’ll make it happen!