The 4 post-covid procurement challenges you need to solve in 2022

In the post-covid world, many industrial companies have been faced with huge challenges in their procurement. It has become obvious that existing tools and procedures are not enough anymore, and holistic visibility is needed for the various workflows and sub-processes of procurement & supply chain. In this blog, we share our priority list of what & how procurement needs to improve in 2022.

Procurement is not what it used to be

“Suppliers are unable to meet their delivery schedules. And even if they are, there will be last-minute changes to delivery quantities. Things are even more difficult when it comes to subcontracting large entities. How does all this affect our production and sales?”

Does this sound familiar?

Changes in the world economy during the past two years have changed the way how we should approach and develop procurement. COVID-19, the Suez Canal blockage, Russian invasion of Ukraine, and rising energy prices are only a few examples of the numerous events that have affected the global market and supply chains in the past years.

What has changed post-covid?

Until recent years, global supply chains were relatively stable, and companies were able to mainly focus on production efficiency and cost optimization. Since availability was not the issue, just-in-time deliveries and minimal stock levels were the pivotal drivers in most manufacturing companies.

Now, in the post-covid world, availability has become The Topic in many industries. Demand surpasses supply, and components & materials aren’t that easy to find. When this problem is repeated at each level of the supply chain and combined with increased shipping costs, delays, and re-routings, the whole system becomes significantly destabilized.

The 4 biggest procurement challenges in 2022

1. Increased manual work

Nowadays, procurement people need to spend significantly more time double-checking things like schedules, quantities, etc. Since everything in purchasing was streamlined to the maximum in the pre-covid world, there is little room for flex in these processes. With the changed circumstances, people simply cannot handle the increased workload manually anymore.

2. Chaotic multi-channel communication with suppliers

One of the root causes for the increased amount of manual work is the way of communicating. It is common, that suppliers have been confirming deliveries by sending an email or using whatever “manual channel” they are used to. This was not too big of an issue before since there were strongly established relationships with the suppliers and few availability issues, but nowadays, procurement people need to expedite and remind suppliers on regular basis. Using a multitude of manual channels for this makes the whole process very time-consuming and chaotic, while the probability of human error grows to a high level.

3. Lack of visibility for production and sales

The above challenges make it extremely difficult for companies to provide up-to-date feedback for their production or sales. A simple question like “do we have these components in stock by Monday?” can require calling suppliers, sending multiple emails, and going through purchase order items & confirmations one line at a time. If the inquiry is about 50 components from 10 different suppliers, imagine how long answering that production planning question will take…

4. Ad-hoc purchases and supplier changes

Due to the continuous shortages of materials and components, companies need to constantly find alternative suppliers. These fast-paced changes also force them to make ad-hoc purchases on short notice. This will lead to the situation where transparency is hindered even more: you cannot use existing EDI connections or any other established channel, since it is not feasible to constantly implement new APIs on such short notice due to the highly varying maturity levels for providing ‘e-feedback’ between suppliers.

How to fix these challenges?

In order to stay competitive, industrial companies need to react quickly to solve the challenges listed above. To do nothing is to admit your defeat.

Based on numerous discussions with c-level decision-makers, we have created a priority list of elements every industrial company must improve in procurement & purchasing in 2022.

Element 1: you need to have a full “status of orders”

Why?

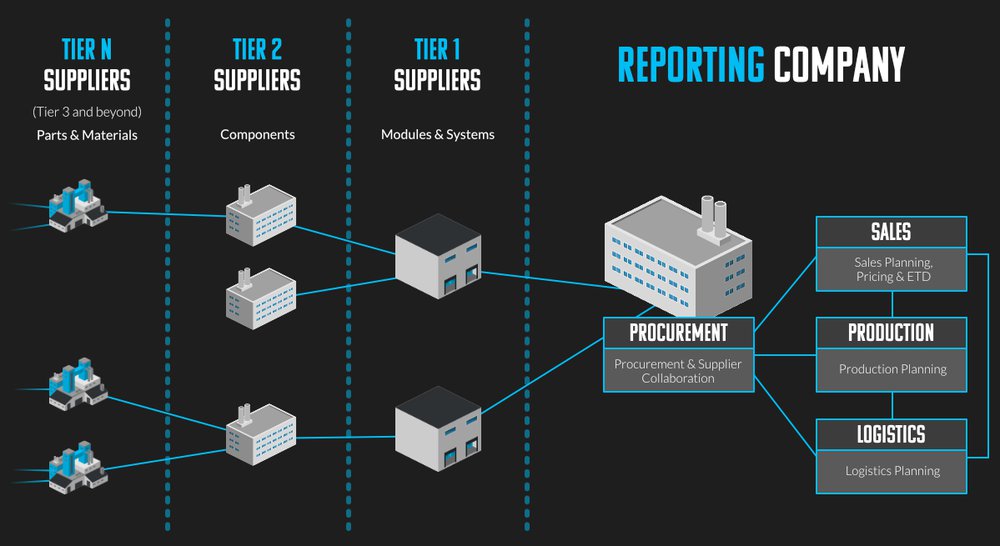

Visibility and transparency play a pivotal role in strengthening and future-proofing procurement models. Companies need to gain a better picture of their suppliers to the tier-n level to enable them to evaluate procurement risks and improve the supplier network for future crises. However, even more important is the visibility and communication inside the company and with tier-one and two suppliers, which enables rapid response to changes and quick decision making.

Procurement affects several stakeholders and departments, and thus up-to-date information must be available without extensive effort. Based on hundreds of conversations with different companies, we have noticed that oftentimes different departments are struggling to access this information when they need it. Delivery statuses are unclear, order confirmations are missing, and production planning/sales are stuck as it is unclear when materials are arriving. The suppliers' role in the whole value chain is increasing and close collaboration will benefit both parties.

How?

- Provide suppliers an easy way to communicate order statuses, schedules, and confirmations, which is not relying on 1:1 interfaces. This can be done with a portal or e-mail workflows for example.

- Implement automated tools for procurement to spot shortages and delays so that they can embrace an exception-based style of management instead of individually checking each PO-line.

- Automate reminders and expediting to notify suppliers about missing order confirmations and delivery confirmations.

By executing these 3 things, purchasing can concentrate on exceptions and anomalies, instead of using the bulk of their time manually maintaining the overall situation awareness. As a result, a lot of extra time is released for critical procurement actions, like safeguarding shortages and to finding alternative suppliers.

Element 2: take full advantage of your ERP with the help of modern digital tools

Why?

Even though legacy ERP systems alone do not meet the changed requirements in post-covid procurement, they still have an important role to fill as the master system for every business area related to procurement. They have their place, but it is crucial to understand they are mainly designed for internal processes, whereas modern digital solutions in procurement rely on seamless collaboration with partners over company boundaries.

Read more in our blog “Focusing on ERP systems in business digitalization can ruin a company”

How?

By utilizing modern digital tools, companies can enhance and leverage their ERP system to yield its maximum potential by providing order confirmations and other crucial documents directly to the ERP in an easy way.

Many in-house systems, such as material requirements planning (MRP) and production planning, rely heavily on master data from the ERP. Without this real-time “status-of-orders” data, they cannot provide accurate feedback which eventually manifests into serious challenges in every phase of the value chain.

Element 3: increase procurement visibility across departments

Why?

In most industrial companies, production planning and sales rely heavily on accurate information provided by the purchasing to run their operations effectively. To trust something so business-critical to be handled manually or on an ad-hoc basis is a massive and unnecessary risk.

How?

By using workflows, rules, and priorities as a basis for automation, it is possible to allocate procurement quantities to high-priority sales and production orders in case of delays or shortages.

In some industries, e.g. the electronics industry, it is very important that track & trace is in place to collect component usage data on the serial number level. With modern tools, this information can be collected as a "by-product" when suppliers send order confirmations. In some cases, this feature can be easily deployed to provide even better added value to the "status of orders".

When executed properly with the right tools, everyone can have a single source of truth 24/7 when it comes to the availability of critical products and components.

Where to begin?

You should start with the most important product groups of your most important suppliers and expand step by step, enabling quick benefits in the short run already. Time is of the essence, so we suggest you act as soon as possible – with modern digital B2B tools, these capabilities can be added to your existing solution landscape in a matter of weeks. If not, then you are considering the wrong tool.

If you are experiencing any of the procurement-related issues mentioned in this blog and are looking to solve them, don’t hesitate to contact us. At Bluugo, we have helped numerous companies digitalize their core business processes in manufacturing, supply chains, and aftermarket services using our unique digital platform Tracking Cloud®. With decades of hands-on experience in business digitalization and a strong background in SAP consulting, our experts really know what works and what doesn’t.

Fill in your contact info and let's set up a discussion!