Choosing the correct maintenance strategy is crucial

Choosing the best maintenance strategy isn’t always a simple process. With the swift development of technology and the digitalization of business, many types of maintenance strategies have become more feasible in the past years – both financially and technologically. These new strategies offer great potential but can also makes choosing your optimal strategy more complicated.

Choosing a maintenance strategy is a crucial decision for any company whose business processes include physical assets. With the right strategy, things should run smoothly, and your machinery, equipment, and other assets will yield their maximum potential. On the other hand, a poorly chosen maintenance strategy can wreak havoc in your operations and cause many kinds of issues such as unexpected downtime, shortened asset life, and maintenance staff inefficiency.

Before analyzing things on a deeper level, let’s take a quick look at the basic maintenance strategies.

Maintenance strategies 101

Reactive maintenance

Reactive maintenance, also known as run-to-fail, is the simplest maintenance strategy available. Its idea is very simple: repair your assets only after they have been run to the point if failure.

Preventive maintenance

Preventive maintenance is a strategy in which maintenance activities are performed regularly on assets when they are still operational to lessen the likelihood of a failure. Preventive maintenance actions can be scheduled based on factors such as time or asset usage. For example, a routine maintenance can be performed on a production machine after every 200 hours of usage or every 2 weeks. Another good example is a maintenance check for a vehicle after each 30 000 km driven.

Condition-based maintenance

Condition-based maintenance is a maintenance strategy that monitors the actual condition of your assets to decide when maintenance activities are required. Maintenance is only be performed when predefined indicators show signs of decreasing performance or upcoming failure. Monitoring of these indicators can be executed in many ways ranging from visual inspections to smart IoT-enabled sensors which continuously send real-time data to your backend systems.

Predictive maintenance

Predictive maintenance is a maintenance strategy that utilizes real-time sensor data, historic data, and complex machine learning models to estimate when an asset or a piece of equipment is likely to fail, so that it can be addressed before reaching the critical point.

Machine learning-powered predictive maintenance is rarely worth the trouble

With today’s advanced technologies, it is possible to create highly accurate solutions that can pinpoint upcoming issues in your assets days in advance using a combination of real-time data, historical data, and machine learning models. You can prevent unplanned maintenance activities, keep your machines running at all times, and plan your maintenance personnel’s work very efficiently – sounds great, right?

When done right, machine learning-powered predictive maintenance can significantly raise your efficiency and productivity, while also decreasing maintenance costs. The twist is that getting to this point usually requires significant investments. Even if you have the budget to start building a solution tomorrow, it is often not possible because you are still missing the most important thing – a sufficient amount of good quality historical data of your assets. Without it, machine learning is like an engine without gas.

Read more about the common challenges of machine learning-powered solutions in our other blog "Avoiding the Pitfalls of Machine Learning".

Example case

For example: a leading offshore oil and gas company introduced a machine learning-powered maintenance solution to nine of its platforms in Africa and Latin America. The results were quite impressive – 20% average reduction in downtime and production increases of over 500 000 barrels of oil annually. BUT, all this did not come easily or cheap.

To achieve these results, a team of 10-15 data scientists worked for over two years, using historical data collected from the past 30 years. During the process, they built and tested over 500 different advanced-analytics models. Read more about the case in an article by McKinsey.

In a nutshell, machine learning-powered predictive maintenance offers great potential but requires a lot of time and effort to set up. It can be the best choice in some – usually very large-scale – use cases but shouldn’t be chosen lightly as your primary maintenance strategy.

Sensor-based maintenance offers the best ROI in most use cases

Sensor-based maintenance (condition-based maintenance with IoT-enabled sensors for monitoring asset condition) is a simple yet effective maintenance strategy. The basic idea is that you equip your assets with IoT-enabled sensors which monitor the asset’s condition based on metrics such as temperature, vibration, or RPM. You then define the normal thresholds in which these metrics vary when the asset is running. If a threshold is exceeded, an automated alert or notification is sent to you signaling that the asset needs attention.

Sensors-based maintenance yields many of the same benefits as preventive and predictive maintenance strategies, but with significantly fewer downsides. In a way, it is a hybrid strategy that combines the best of both worlds:

- Identify issues before they lead to asset failure

- Minimize asset downtime

- Avoid unnecessary maintenance checks and activities

- Much faster to implement than machine learning-powered predictive maintenance

- Doesn’t require existing historical data

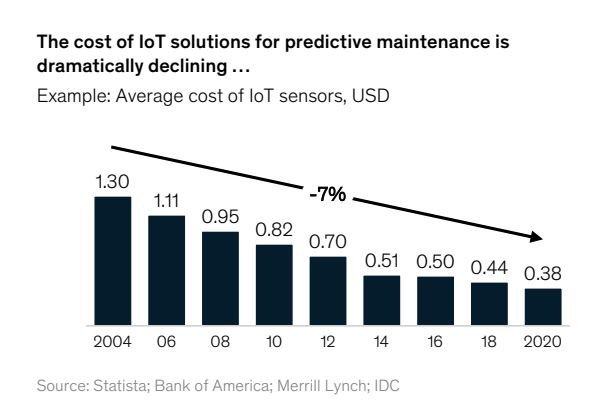

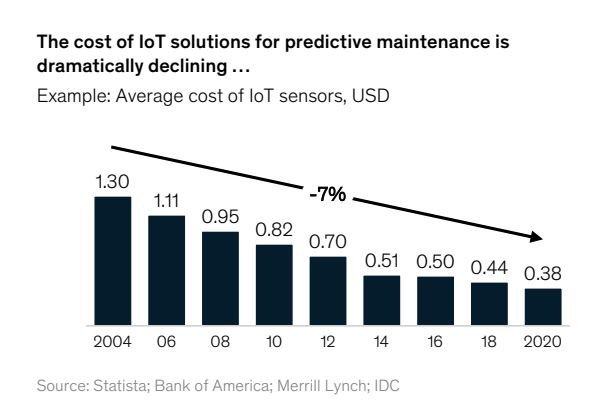

One of the pivotal challenges of sensor-based maintenance has historically been the high cost of hardware. IoT-enabled sensors used to be very expensive, which made many uses cases with high numbers of assets financially unfeasible – especially, if the sensors had to use their own power sources which had to be changed periodically. However, the prices of IoT devices have continued to decrease steadily with an average yearly rate of 7% for years now, making more and more use cases financially feasible.

The decreasing hardware costs have made many new use cases financially feasible in the past years. Image source: The future of maintenance for distributed fixed assets, McKinsey 2020.

Implement a sensor-based maintenance solution in 8 weeks

Bluugo’s Tracking Cloud® is a cloud-based SaaS product that offers everything you need to implement new digital solutions for your maintenance & field service operations – in a matter of weeks!

We provide all the required software, hardware, and sensors as a part of the service. If you already have some sensors in use, those can also be utilized – Tracking Cloud’s built-in APIs allow us to easily connect to any existing hardware.

Read more about or maintenance solutions here or get in touch today! We are happy to show you how Tracking Cloud® works in action and tell how it has helped our customers to revolutionize their maintenance actions. Fill in your contact info here, and let’s set up a product demonstration – no strings attached.